Sailtran Energy Storage Connector Test and Inspection Project

Saichuan electronic energy storage connector is used for positive and negative high voltage connection between battery packs of chemical energy storage system. Install energy storage systems quickly, safely and cost-effectively for applications up to 1,500 V and 400 A. There are a variety of models to choose from, which can adapt to high-voltage cables with different wire diameters of 10mm²~120mm². There are also easy-to-use copper bus connectors. We have advanced crimping technology and equipment to provide energy storage connector with integrated cables.

Saichuan Electronics has passed the IATF16949 and ISO9001 quality management system certification. It has an independent full-project laboratory of 1,200 square meters, a team of more than 50 high-precision engineers, and more than 50 sets of various testing equipment and instruments, which can achieve electrical performance, mechanical performance, environmental performance and 4 categories of failure analysis, nearly 30 tests and tests. Our energy storage connectors have undergone a series of testing and verification, and can meet and lead the testing requirements. The following are some of the inspection items I have listed for our energy storage connectors.

1.1 Visual inspection

Testing method :

Item 5.1.8.3 of USCAR-2-2013: Visual inspection of experimental samples

Inspection requirements:

Item 5.1.8.4 of USCAR-2-2013: With the help of a 10x magnifying glass, no defects such as degradation, cracking and deformation that would affect its function or reduce the appearance quality should be seen on the connector assembly. The coating cannot be damaged, the part raw material is directly visible, and other acceptance criteria are detailed in each test experiment.

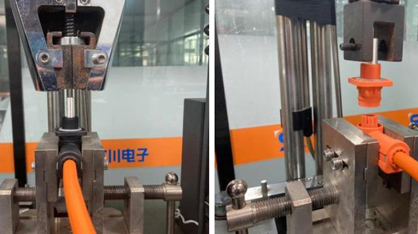

1.2 Mechanical life

Testing method:

According to the special needs of customers: complete 100 mating and unplugging times for each pair of connectors or terminal pairs.

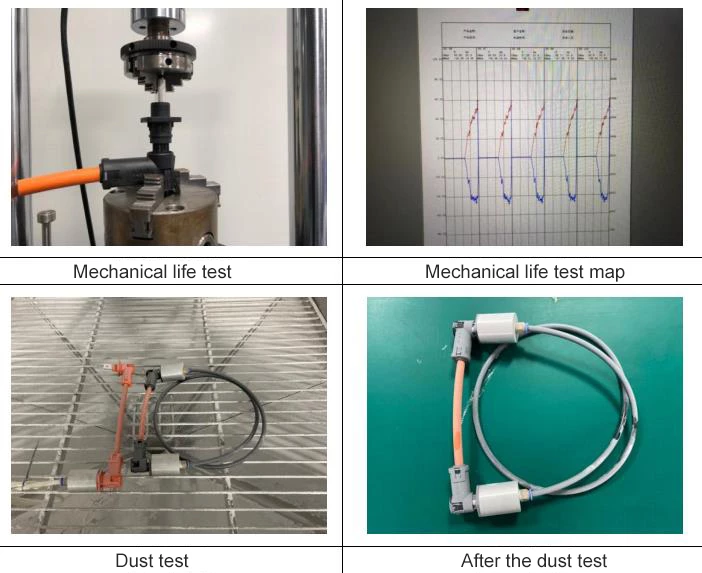

1.3 Dustproof

Testing method:

In GB/T 4208-2017, No. 13.4: The maximum pressure difference is 2kPa (20mbar), and the pumping speed is lower than 40 times the volume of the shell per hour, the test should be completed after the continuous pumping of 80 times the volume or 8 hours. stop

Inspection requirements:

13.6.2 of GB/T 4208-2017: After the test, there is no obvious dust deposition in the shell, that is, the test is considered qualified.

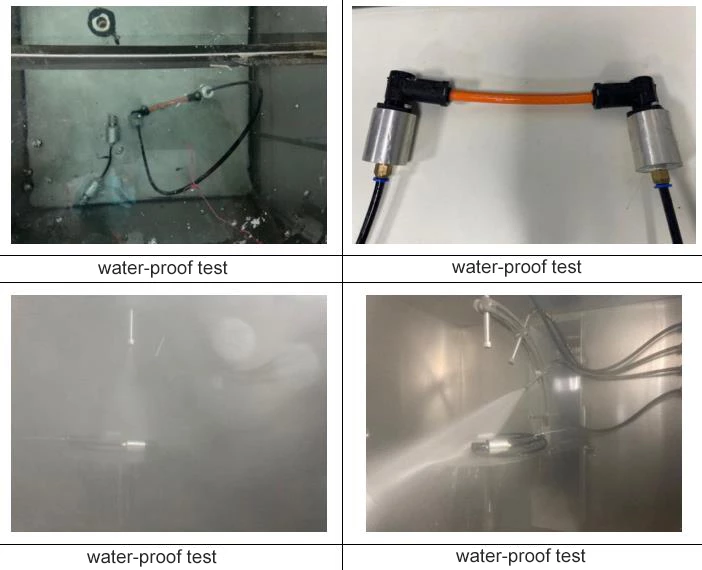

1.4 Waterproof

Testing method:

Article 14.2.8 of GB/T4208-2017: The tested enclosure is fully immersed in water according to the installation state specified by the manufacturer, and meets the following conditions:

1. The lowest point of the enclosure with a height of less than 850mm should be 1000mm below the water surface;

2. The highest point of the enclosure with a height equal to or greater than 850mm should be 150mm below the water surface;

3. The test duration is 30min; the difference between the water temperature and the sample temperature is not more than 5K;

Inspection requirements:

Refer to Article 7.28.2 in the test program: after the test piece is stabilized in water, no obvious bubbles can be seen in the water. After the test, dry the outside of the test piece, pull out the pair of inserts, and there should be no visible liquid inside the test piece.

1.5 Splash-proof

Testing method:

Clause 5.6.7.3 of USCAR-2-2013:

1. The CUT must include all applicable wedges (TPAs, PLRs, seals, etc.). Number each paired connector pair.

2. Mount the connector under test on the equipment bracket with the connector flat on the turntable.

3. Place the sprayer at 0°, start spraying and turn the turntable.

4. While the table is rotating, spray the connector under test for 30 seconds. Repeat the above for each spray angle specified in Table 5.6.7.3-1.

5. Remove the sample from the chamber, shake off excess liquid, and carefully dry all outer surfaces of the sample. Immediately perform the insulation resistance test of 5.5.1.

6. At the end of the test, measure the CUT/TUT as required by the appropriate test sequence sheet.

Inspection requirements:

Article 5.6.7.4 of USCAR-2-2013: Insulation Resistance≥100MΩ

The above are some test items of Saichuan electronic energy storage connector. According to the inspection standards, all items have passed strict test verification and meet customer requirements. Other test items will be shared next time!