Saichuan Electronic CCS2 charging socket power terminal fixed structure patent

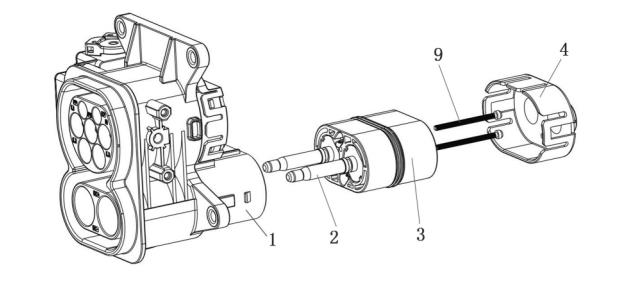

The problem of energy shortage and environmental pollution is becoming more and more serious, which has always plagued the development of the automobile industry and related industries. Since new energy vehicles can solve the above problems to a certain extent, new energy vehicles have been vigorously developed in recent years. In the future, the market demand for new energy vehicles will increase significantly, and the demand for charging sockets related to new energy vehicles will also rise accordingly. The CCS2 charging socket includes terminal pins, accommodating the terminal pins, a waterproof and insulated plastic body, a pin press plate that semi-fixes the terminal pins in the plastic body, etc. In the prior art, the pins of the charging socket are fixed by screwing the terminals into the socket. The needle presser plate of the needle is fixed on the plastic body, as shown in Figure 1, because the tail of the socket is thrown out, it is very inconvenient for the manufacturer to lock the screw from the direction of the outlet, the production efficiency is low, and the process is complicated.

The utility model provides a power terminal fixing structure of a ccs2 charging socket in order to solve the problems in the prior art that the pin pressing plate of the terminal pin is fixed to the plastic main body by screws, the process is complicated and the reliability is poor.

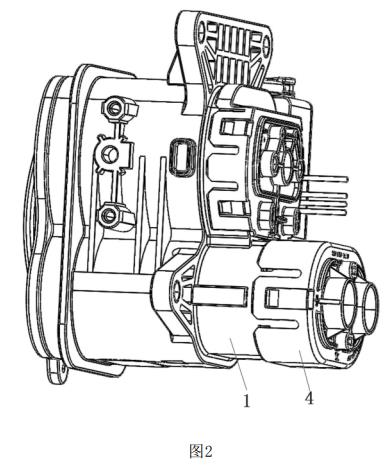

A power terminal fixing structure of a CCS2 charging socket, comprising a plastic body, a terminal pin, a pin presser plate and an outlet cover, by symmetrically arranging spring arms on the pin presser plate, and setting a limit hole matched with the spring arm on the plastic body, During the assembly process, the elastic arm of the needle presser is squeezed inward by the plastic main body. After the assembly is in place, the elastic arm springs up and buckles into the limit hole on the plastic main body to prevent the needle presser from retreating and fix the terminal pins on the plastic main body. Inside: After the needle presser plate and the plastic main body are assembled in place, the outlet cover is assembled, and a baffle plate matching the needle presser plate is installed inside the outlet cover. The elastic arm of the needle presser continues to be squeezed inward to realize the secondary lock (TPA structure). Improve reliability.