New energy vehicle high voltage wiring harness design and wire requirements

The application scenarios of new energy high-voltage cables mainly include high-voltage lines in the car, charging guns/charging piles, and on-board charging. The high-voltage wiring harness in the car is mainly used to provide high-voltage power supply for new energy vehicles. It is a high-safety component with the characteristics of high voltage/high current and large number of large-diameter wires, which also makes the design of new energy high-voltage wiring harnesses face many challenges. Today, Saichuan Electronics will take you to understand the design and wire requirements of high-voltage wiring harnesses in new energy vehicles.

Characteristics of high-voltage wiring harness in new energy vehicles

1. High voltage/high current

The battery voltage of new energy vehicles can reach 600V, and the corresponding wire withstand voltage level can reach 300A. The battery voltage of traditional fuel vehicles is generally 12V, and the corresponding wire withstand voltage level is less than 60V.

2. The number of wires with large diameter is large

New energy vehicles need to use large diameter wires in high-voltage batteries, inverters, transformers, low-voltage batteries, air-conditioning compressors, etc., and the number is very large.

Challenges faced by the high-voltage wiring harness in the car

Due to the characteristics of large voltage/high current and large number of large-diameter wires, the design of high-voltage wiring harnesses in vehicles faces challenges such as safety, wiring, shielding, weight, and cost. Facing these challenges, we have summarized some countermeasures.

1. Security

In the face of safety challenges, some countermeasures need to be taken in the selection and sealing of wires in the car

(1) wire selection

Use high-voltage wires 600V/900V (AC) (refer to ISO19642);

Adopt wall thickness high line, wall thickness 0.6mm-1.1mm;

Using heat-resistant wire, heat-resistant 150 degrees or above

Silicone rubber wire, cross-linked polyethylene/cross-linked polyolefin material can be selected

(2) sealed

Matched with high-voltage connectors, it is sealed with wire seals, heat-shrinkable tubes, Pass-thru seals, rubber parts, etc. for waterproof and dustproof (IP67, IP69K). The wire is required to have good roundness, dimensional stability, and aging performance.

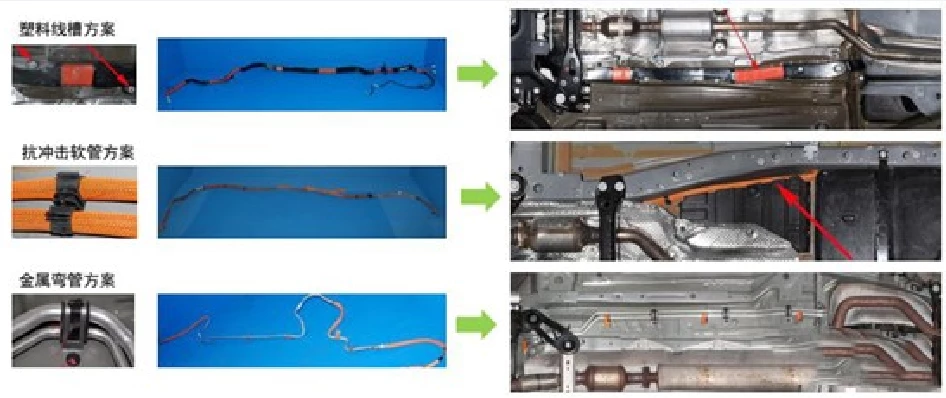

2. Wiring

The layout of the high-voltage wiring harness in the vehicle has the following requirements:

(1) In the case of static load, the minimum turning radius is 4 times the outer diameter of the wire;

(2) In the case of dynamic load, the minimum turning radius is 8 times the outer diameter of the wire;

(3) The minimum distance between high and low voltage conductors is not less than 100mm;

(4) The distance from the outlet end of the high-voltage connector to the first fixed point is not more than 100mm, and the distance between adjacent fixed points is generally not more than 150~200mm;

(5) The high-voltage wiring harness should be arranged at the bottom of the vehicle as much as possible;

(6) Wire selection tough wires such as silicone rubber wires, flexible cross-linked polyolefin wires.

3. Shield

Because of the electromagnetic field interference generated by the high voltage and large AC of new energy vehicles, as well as the electromagnetic interference generated by the rapid on-off of electrical components, considering the factors of electromagnetic interference, the entire high-voltage system is completely covered by the shielding layer. Then the measures for high-voltage wire harness shielding electromagnetic interference are:

4. Weight

For new energy vehicles, lightweight is very important for the improvement of cruising range. Then the weight of the wiring harness can start with the selection of materials. The conductor material can be a new type of wire conductor, such as a new type of aluminum wire; the insulation material can be made of low-density materials, and at the same time thin-walled processing.

5. Cost

At present, the high-voltage wires in the car are mainly imported, and the wire threshold is relatively high. The output of mass-produced models in the early stage is small. New energy vehicles are facing greater cost pressure, and more domestic resource development is required.

6. Environmental protection

The high-voltage wiring harness in the car needs to use low-volatility, low-VOC, and low-odor materials.

After more than ten years of live application in vehicles, Saichuan Electronics has accumulated a wealth of experience in customizing automotive electrical connection systems. In terms of new energy vehicles, our products have passed strict laboratory and road running tests for complete vehicles. It maintains stable, reliable and durable performance during operation; it also has excellent market performance in the field of energy storage.

60,000 kilometers of road reliability assembly test to ensure product reliability;

The conductor is made of multi-strand oxygen-free copper wire, which has strong flexibility, a withstand voltage of 1500V, and a current carrying capacity of 20~300A;

The thread is made of XLPE material, which is more durable;

Suitable for extreme temperature environment, temperature resistance -40~125 degrees Celsius;

Protection level up to IP68, IP69K.